Precision seeding allows the user to define the distance between each seed released by the seeding disc. The FieldMate control system manages the speed of the seeder drive motor to ensure the distance between the seed is kept at the spacing entered into the monitor. Spacing between each seed can be adjusted in millimeter steps.

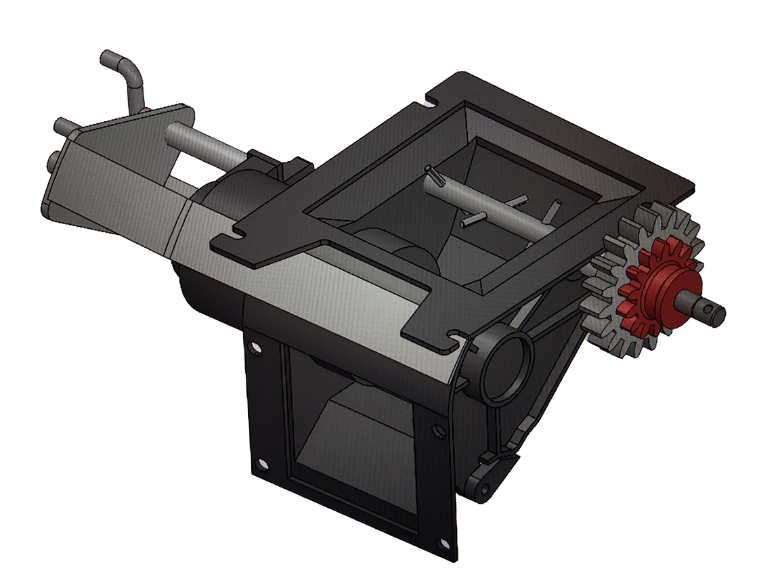

Spacing between each seed planted is electronically set in the monitor. One electric motor will typically drive up to 5 seeder units, with a max of 2 motors per monitor. The second can be configured to drive another seeding shaft or a fertilizer box. Fertilizer can be applied in KG per hectare rates.

Calibration of the system is achieved by entering the gear ratio setting in the monitor, this is the ratio between the motor drive and the final seeder driving shaft. This ensures that if you set the spacing between seeds to 55 millimeters on the screen, then you will get 55 millimeters spacing in the paddock. No other adjustment factors are required; as what you set is what you get.

The setting of the ratio can be verified by setting the seeder disc to rotate 10 times; at the end of 10 rotations the seed disc should be exactly where it started from. Forcing the seed discs to turn 10 times is an easy way to observe that all planters are operating correctly and prove the drive system is accurate as it stops at the exactly 10 rotations across all seeder units.

When in use the monitor displays various information:

- Seed Spacing

- Drive motor RPM

- Target RPM for the Drive motor

- Area drilled

- Distance drilled, working rate, Sub area,

- Hour timers

- Clock and calendar

- Seeds drilled (computed from motor feed back, does not account for tube blocks etc)

- Seeds per hectare (computed from motor feed back, does not account for tube blocks etc)

- Motor health

- Instant Report on screen of all work done

- Report down loading to office computer (optional)

- Low bin monitoring (optional) … This feature will alert the user that a bin level is low. Can be used to monitor multiple bins.

- GPS mapping control (optional) … This feature will give instruction to the GPS mapping system to start mapping when the drill is planting

- GPS seeding control (Optional) … This feature will allow the GPS to turn the drive motor on/off as required to start/stop at the headlands

Technical Specs

- Supply voltage

- 5 to 15 Volts

- Standby Current

- 300 - 600 mA

- Supply Protection

- automotive load dump protected

- Reverse protection

- 500 volts

- Sensor input protection

- +/- 30 volts protection

- Data retention

- 20 years

- Temperature

- 10 to + 50 degree/C

- Sensor polarity

- Negative switching only.

- Processor

- 32 bit 160Mhz

- Motor Max Current

- 20 amps

- Motor stall current lockout

- 15 amps

- Motor normal operating current

- 3-10 amps

- Max fan monitoring speed

- 7000 RPM

- Right To Repair

- Supported

- Regulation Certification

- C-Tick, CE