FieldMate E-drive is supplied in either of two solution configurations

Option 1: Singular Seeding Mode.

This mode allows the user to define the distance between each seed released by the seeding disc. The FieldMate control system manages the speed of the seeder drive motor to ensure the distance between the seed is kept at the spacing entered into the monitor. Spacing between each seed can be adjusted in millimeter steps.

Spacing between each seed planted is electronically set in the monitor. One electric motor will typically drive up to 5 seeder units, with a max of 2 motors per monitor. The second can be configured to drive another seeding shaft or a fertilizer box. Fertilizer can be applied in KG per hectare rates.

Calibration of the system is achieved by entering the gear ratio setting in the monitor, this is the ratio between the motor drive and the final seeder driving shaft. This ensures that if you set the spacing between seeds to 55 millimeters on the screen, then you will get 55 millimeters spacing in the paddock. No other adjustment factors are required; as what you set is what you get.

The setting of the ratio can be verified by setting the seeder disc to rotate 10 times; at the end of 10 rotations the seed disc should be exactly where it started from. Forcing the seed discs to turn 10 times is an easy way to observe that all planters are operating correctly and prove the drive system is accurate as it stops at the exactly 10 rotations across all seeder units.

When in use the monitor displays various information:

- Seed Spacing

- Drive motor RPM

- Target RPM for the Drive motor

- Area drilled

- Distance drilled, working rate, Sub area,

- Hour timers

- Clock and calendar

- Seeds drilled (computed from motor feed back, does not account for tube blocks etc)

- Seeds per hectare (computed from motor feed back, does not account for tube blocks etc)

- Motor health

- Instant Report on screen of all work done

- Report down loading to office computer (optional)

- Low bin monitoring (optional) … This feature will alert the user that a bin level is low. Can be used to monitor multiple bins.

- GPS mapping control (optional) … This feature will give instruction to the GPS mapping system to start mapping when the drill is planting

- GPS seeding control (Optional) … This feature will allow the GPS to turn the drive motor on/off as required to start/stop at the headlands

Option 2: Seed weight per hectare planting.

This mode allows the user to plant a defined seed or fertilizer weight for a given area of land. The monitor can control up to 4 motors. One motor could run the seed box, a second motor could run the fert, while a third motor could run a small seed box and a four motor a slug bait metering unit or even an auto greaser or electric fan.

Calibration is fast, simple and accurate! As the calibration weight can be entered into the monitor with single gram resolution. During calibration the monitor when instructed to will drive motor so it rotates a perfect 10 turns, to complete the calibration cycle. The material dispensed is collected and weighed, the weight recorded is the calibration weight.

After the calibration weight has been entered into the monitor and required drilling rates are entered into the monitor, you are ready to go! While drilling the monitor displays various information including drilling rate, area drilled and the motor RPM’s for the current setup. Other information available is the time taken to complete a job, the total weight of material released for each bin.

The “Pre-Drill Prediction” feature is a special bar graph display in the Calibration Weight/Rate setup screens that allows the user to know exactly whether the seeding rate and calibration weight entered into the monitor are valid for the drilling rate. In some cases the calibration weight will have to be decreased if very low seeding rates are to be achieved… Or maybe increase the calibration weight if a heavy drilling rate is needed. The “Pre-Drill Prediction” feature allows the operator to know that the motor is going to be able to delivery the required planting rate even before the tractor moves, saves time and makes every things very predictable. Helping get things right the first time.

We have optional extra’s that may be of interest:

- Instant Rate Reduction Unit ( Allows the drilling rate for any bin to be instantly reduced by 25%, 50% or 75% at the flick of a switch)

- Accord metering unit to FieldMate Motor adaptor plate ( Makes air seeder conversions quick and simple and best of all can be done on farm)

- Low bin sensors

- Fan Speed sensors

When in use the monitor displays various information:

- Drilling rate in Kg/Hect

- Motor speeds

- Area Drilled

- Distance drilled, working rate, Sub area,

- Hour timers

- Clock and calendar

- Seed weight drilled (computed from motor feed back, does not account for tube blocks etc)

- Motor health

- Instant Report on screen of all work done

- Report down loading to office computer (optional)

- Low bin monitoring (optional) .. This feature will alert the user that a bin level is low. Can be used to monitor multiple bins.

- GPS mapping control (optional) .. This feature will give instruction to the GPS mapping system to start mapping when the drill is planting

- GPS seeding control (Optional) .. This feature will allow the GPS to turn the drive motor on/off as required to start/stop at the headlands

The FieldMate monitor is simple and easy to use, and does not take up lots of space on the drill. The setup is straight forward.

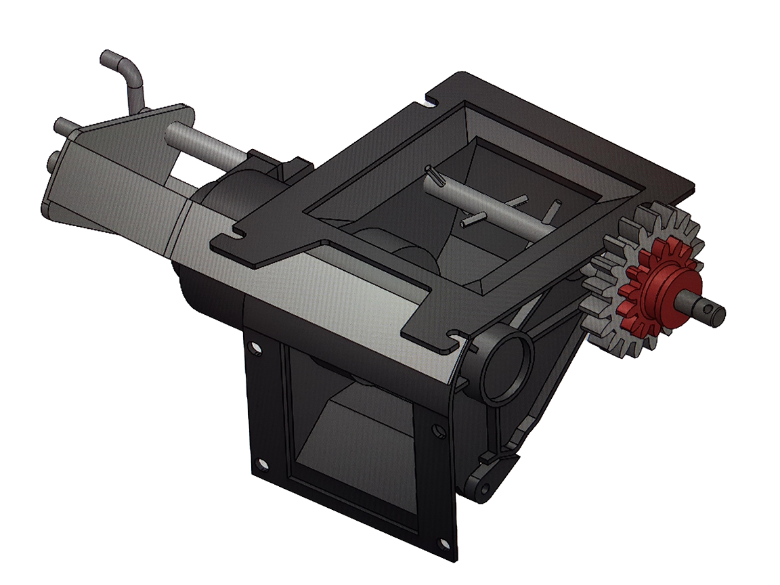

Designed to be fitted to both new seed drills and older drills, air seeders or gravity drills. Replacing the mechanical gearbox and turning an older drill in to a new machine with easy calibration and accuracy.

Motor protection is simple and effective, in the event of a motor jam (ie: the fertilizer bin shaft is jammed tight with fertilizer), the monitor will attempt to run the motor, if the motor does not start rotating in 5 sec as the power is increased into the motor, then the motor is shut down and the monitor alerts you that a motor jam has occurred. The motor will not be restarted until the monitor is turned on/ off .

The kit can be supplied fully built up into a plug and go solution with wiring loom and all sensors ready to plug in. Custom wiring looms are supplied to perfectly fit your drill setup.

Talk to us , we are here to help.